Description

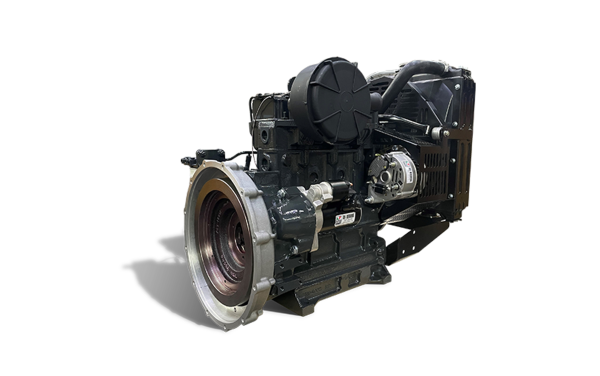

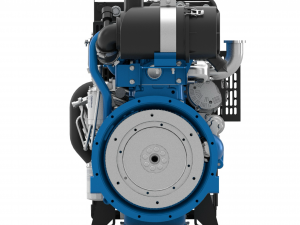

Product Overview

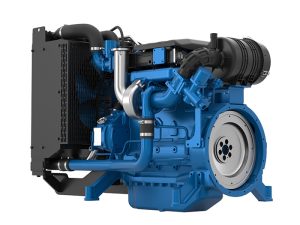

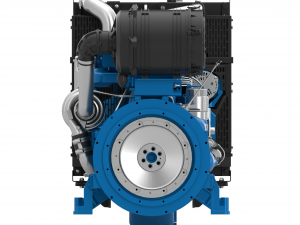

The **Lister Petter LPW** series comprises rugged and reliable industrial diesel engines designed for generator, pump, and industrial use in **unregulated emissions territories**. With fixed‑ or variable‑speed configurations, they deliver continuous power ranging from **6.8 kW to 41.3 kW**, at speeds from **1,500 rpm to 3,600 rpm**, depending on the model. Built for extreme conditions (up to 52 °C ambient, cold starts down to −32 °C) and featuring 500‑hour service intervals. :contentReference[oaicite:4]{index=4}

Range of Models

- LPW2 (2‑cylinder, 6.8–14.7 kW)

- LPWX2 – extended spec variant

- LPW3 (3‑cylinder, 11.3–22.1 kW)

- LPWX3 – extended performance version

- LPW4 (4‑cylinder, 15.0–28.0 kW)

- LPWX4 – high‑spec 4‑cylinder version

- LPWT4 (4‑cylinder turbocharged, 18.9–37.5 kW)

Key Features

- Durable Design: Water‑cooled, cast‑iron block with spin‑on full‑flow oil filter and gear‑driven positive displacement oil pump

- Fuel System: Direct injection, individual cylinder pumps, self‑vent fuel system and agglomerator filter

- Flexible Speeds: Configurable from 1,500 up to 3,600 rpm (fixed or variable speed)

- High Ambient Capability: Operating up to 52 °C; cold start to −32 °C

- Maintenance Intervals: Oil & filter service every 500 hours for long service life

- No Regulated Emissions – ideal for unregulated regions; models below 19 kW also meet EU Stage III A

Technical Specifications

| Model Range | LPW2, LPWX2, LPW3, LPWX3, LPW4, LPWX4, LPWT4 |

|---|---|

| Continuous Power Output | LPW2: 6.8–13.4 kW; LPW3: 11.3–20.1 kW; LPW4: 15.0–28.0 kW; LPWT4: 18.9–37.5 kW (ISO 3046) |

| Overload Power | Up to 14.7, 15.3, 16.5, 20.8/26.2 kW respectively depending on rpm |

| Speed Range | 1,500 to 3,600 rpm (fixed/variable) |

| Cylinders & Displacement | 2/0.93 L (LPW2), 3/1.29 L (LPW3), 4/1.72 L (LPW4), turbo LPWT4 same 4‑cyl |

| Bore & Stroke | 86 mm × 80 mm across all models |

| Fuel Consumption (Max Load) | LPW3 ~3.8–5.9 L/hr; LPW4 ~4.6–7.8 L/hr; LPWT4 ~6.0–10.6 L/hr |

| Cooling System | Liquid‑cooled with belt‑driven pump, thermostat, optional radiator & fan guard |

| Dimensions & Weight (LPW2) | Approx. 699 × 512 × 647 mm; 158 kg |

Standard Equipment

- Heavy‑duty air cleaner and inlet manifold heater plug

- Fuel lift pump and agglomerator filter system

- Radiator package with fan, belt guard (if radiator-cooled)

- Spin‑on oil filter; gear‑driven lubricating oil pump

- 12 V electric start system (24 V optional)

- SAE5 flywheel housing; flywheel with ring gear

- Operator’s handbook included

Emissions & Compliance

- Unregulated emission engines; no specific certification needed

- Models below 19 kW comply with EU Stage III A exhaust limits

- Rated and tested according to ISO 3046 power standards

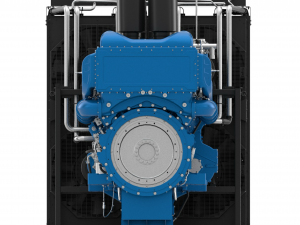

Applications

- Industrial generators, pump drives, compressors, and hydraulic systems

- Reliable performance in harsh and remote environments up to 52 °C

- Low-maintenance continuous duty for OEM and retrofit applications