Description

Product Overview

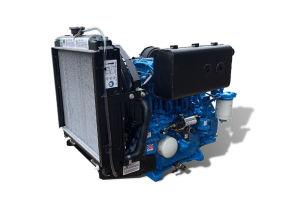

The Lister Petter LP Series water-pump engines are purpose-built, liquid-cooled diesel engines optimized for industrial, municipal, and agricultural pumping applications. Designed for high durability and long maintenance intervals, they support fixed-speed operation (1,500–3,000 rpm) and deliver continuous power in the range of 6.8 to 34.0 kW (9.1–45.6 bhp). They are rated for reliable continuous duty in ambient temperatures up to 52 °C and can cold-start in environments as low as −32 °C.

Key Features

- Robust Cooling System: Thermostatically controlled, belt-driven water pump with radiator and fan (guarded).

- Long Service Interval: Oil and filter change interval up to 500 hours, depending on conditions.

- Fixed-Speed Operation: Available in 1,500; 1,800; 3,000; and 3,600 rpm variants, ensuring stable pump performance

- Cold-Start Capability: Designed to start reliably down to −32 °C (−25.6 °F).

- Fuel System: Self-venting fuel system with individual injection pumps, fuel lift pump, and agglomerator filter for clean, reliable fueling.

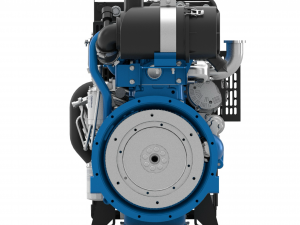

- Durable Construction: Heavy-duty air cleaner, SAE-5 flywheel housing, and ring-gear flywheel standard.

- Starter & Charging: 12 V electric start with alternator; 24 V optional.

- Cold Climate Enhancements: Inlet manifold heater plugs and safety switches included.

Applications

- Municipal water supply and irrigation pumping stations

- Agricultural irrigation systems

- Industrial pump drives for high-pressure or high-volume systems

- Remote or unattended pumping installations with long service intervals

Technical Specifications

| Model Range | LPW2, LPWX2, LPW3, LPWX3, LPW4, LPWX4, LPWT4 |

|---|---|

| Speed (fixed) | 1,500 | 1,800 | 3,000 | 3,600 rpm (varies by variant) |

| Continuous Power | 6.8–34.0 kW (9.1–45.6 bhp) at rated speed |

| Cold Start Capability | Down to −32 °C (−25.6 °F) |

| Maximum Ambient Operating Temperature | 52 °C (122 °F) continuous duty |

| Injection System | Direct injection diesel |

| Number of Cylinders | 2 (LPW2), 3 (LPW3), 4 (LPW4, LPWT4) |

| Bore × Stroke | 86.0 mm × 80.0 mm |

| Displacement | 0.93 L (LPW2) | 1.395 L (LPW3) | 1.860 L (LPW4, LPWT4) |

| Compression Ratio | 18.5:1 (naturally aspirated) / 16.2:1 (LPWT4 turbo) |

| Firing Order | 1-2 (LPW2) | 1-2-3 (LPW3) | 1-3-4-2 (LPW4 / LPWT4) |

| Dry Weight (approx.) | ≈ 247 kg (LPW2) / 150 kg (LPW3) / 180 kg (LPW4) |

| Lubrication | Gear-driven positive displacement pump, full-flow spin-on filter |

| Oil Capacity | LPW4: 11.5 L sump (typical) |

| Cooling System |

Standard Equipment

- Inlet & exhaust manifolds

- Heavy-duty air cleaner

- Fuel lift pump

- Mechanical governing (governor) system

- Self-venting fuel system with individual injection pumps

- Fuel filter / agglomerator

- Thermostatically controlled coolant pump + radiator + fan guard

- Gear-driven positive displacement lubricating oil pump

- Spin-on full-flow oil filter

- Polyvee fan / alternator drive belt

- Inlet manifold heater plugs

- Safety switches for temperature and oil pressure

- Flywheel with ring gear & SAE-5 flywheel housing (SAE-4 optional)

- 12 V starter motor & 12 V alternator (24 V optional)

- Oil pressure & coolant temperature senders / switches

- Fuel control solenoid (energized to run)

- Skid-base packing (mounting)

- Cobalt-blue finish (standard)

- Operator’s handbook (English)

Optional Equipment

- Radiator options (pusher or puller fan) with full guarding

- Oil cooler for high-temperature duty

- 24 V electrical system

- Deep-sump (increased oil capacity)

Compliance & Emissions

- These LP-Series engines are designed primarily for unregulated-emissions territories.

- Some models under 19 kW comply with EU Stage 3A emissions regulations.

- Rated and tested against ISO 3046 power standards.

Differentiators & Benefits

- Long Maintenance Intervals: The 500-hour service schedule reduces downtime and total cost of ownership.

- Wide Operating Range: Designed to function reliably in extreme ambient conditions (−32 °C to +52 °C).

- High Durability: Sturdy cast components and reliable fuel system minimize wear and maintenance risk.

- Fuel Flexibility: Approved for biodiesel blends (up to 20% per ASTM D6751 and EN14214).

- Compact & Scalable: Multiple cylinder options (2, 3, 4) allow flexibility for different power needs.

- Proven Provenance: Backed by Lister Petter’s legacy and global parts/manufacturer support network.

Related Models & Variants

Within the LP family, Xanthis.gr can supply:

- LPW2 / LPWX2: Compact 2-cyl models for lighter pump applications.

- LPW3 / LPWX3: 3-cyl options balancing power and footprint.

- LPW4 / LPWX4: 4-cyl naturally aspirated versions for higher output.

- LPWT4: 4-cyl turbocharged model for enhanced performance and torque.

Why Choose Lister Petter?

As a globally respected name in industrial and marine power systems, Lister Petter combines more than a century of engine-design expertise with an extensive aftermarket partner network. Their LP Series offers XO-grade reliability, low lifecycle cost, and proven performance in the harshest environments — making it a smart choice for all pump-driven installations.

Summary

If your project demands a high-quality, low-maintenance, and proven diesel engine for water-pumping duty — whether for municipal supply, agriculture, or industrial use — the Lister Petter LP Series delivers. Contact Xanthis S.A. today to discuss the right LP model for your capacity, speed, and site requirements.