Description

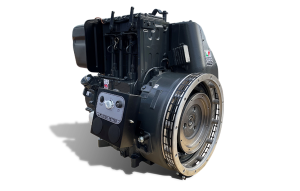

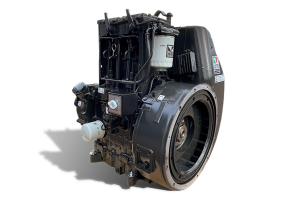

Product Overview

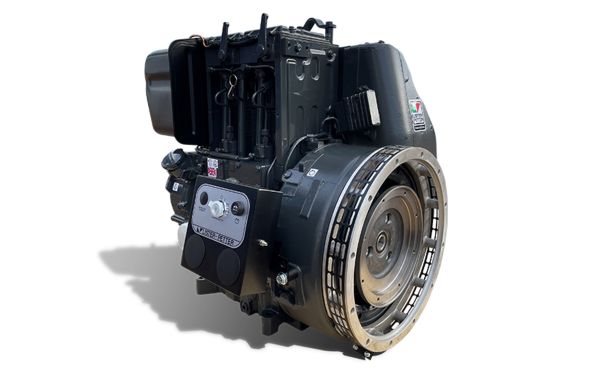

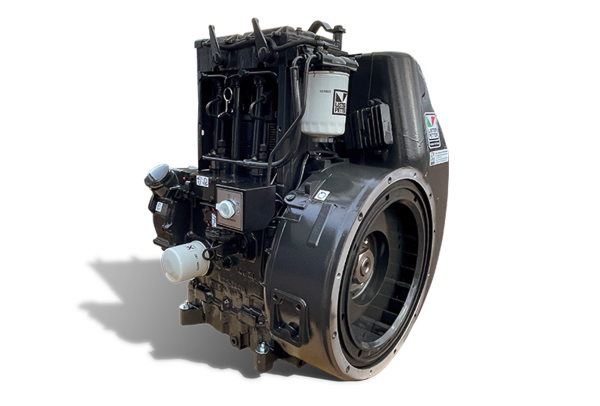

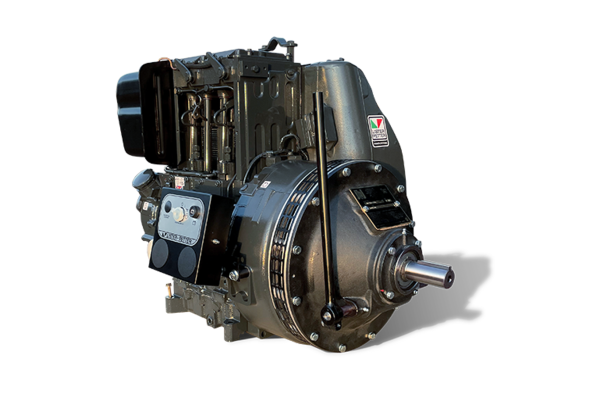

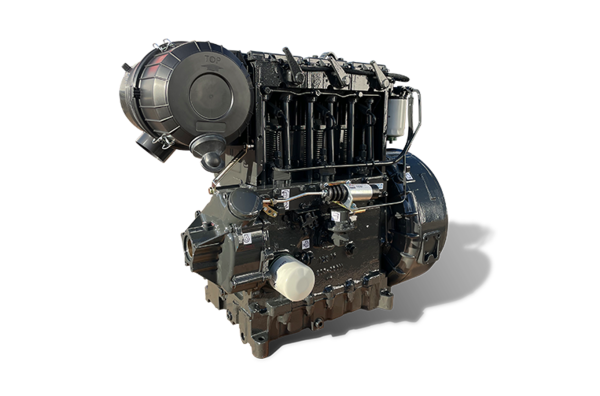

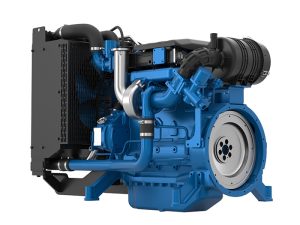

The Lister Petter **TR Industrial Engines** are compact, robust diesel engines designed for use in **unregulated emissions territories**. Built for reliability and low maintenance, they support **continuous operation in ambient temperatures up to 40 °C (104 °F)** and are suitable for a wide range of industrial and auxiliary power applications.

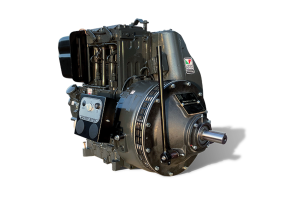

Fixed-speed options cover **1,500 – 1,800 rpm**, while variable-speed models operate at **1,500 – 2,500 rpm**, delivering power from **5.5 kW to 28.5 kW** (≈ 7.4–38.2 bhp), depending on the model.

The TR range includes **TR1**, **TR2**, and **TR3**.

Key Features

- Compact & Durable: Designed for tight spaces without compromising reliability.

- Long Service Intervals: Oil and filter changes every 250 hours, depending on operational conditions.

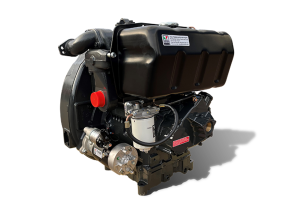

- Cooling System: Oil cooling via airflow over deep crankcase finning and flywheel-mounted cooling fan.

- Fuel System: Self-venting fuel system with lift pump and fuel injection pump for consistent delivery.

- Filtration: Medium-duty air cleaner and spin-on lubricating oil filter.

- Start & Safety: 12 V starter motor, fuel control solenoid (energised to run), and safety switches included.

- Operation Flexibility: Available in fixed and variable speed configurations to match industrial drive requirements.

- Skid Mounting: Standard skid base packing allows secure installation.

- Operator Support: Comprehensive handbook included (English).

- Optional Upgrades: 12 V battery charge windings, ventilated SAE4:4/5 adaptors, 6.5′ or 7.5′ drive members, heavy-duty air cleaner.

Technical Specifications

| Specification | TR1 | TR2 | TR3 |

|---|---|---|---|

| Number of Cylinders | 1 | 2 | 3 |

| Displacement | 0.55 L | 1.10 L | 1.65 L |

| Fixed Speed | 1,500 / 1,800 rpm | ||

| Variable Speed | 1,500 – 2,500 rpm | ||

| Power Output | 5.5 kW | 14.0 kW | 28.5 kW |

| Ambient Operating Temperature | Up to 40 °C | ||

| Service Interval | 250 hours | ||

| Rotation | Anti-clockwise (flywheel end view) | ||

Standard Equipment

- Medium-duty air cleaner

- Oil cooling by airflow over deep crankcase finning

- Inlet and exhaust manifolds

- Fuel injection pump and self-vent fuel system

- Fuel filter

- Fuel lift pump

- Self-regulating plunger type lubricating oil pump

- Spin-on lubricating oil filter

- Decompressor levers

- Flywheel with cooling fan

- SAE flywheel housing

- Mechanical governing

- 12 V starter motor

- Safety switches

- Fuel control solenoid (energised to run)

- Standard skid base packing

- 250 hour service intervals

- Operator’s handbook (English)

Optional Items

- 12 V battery charge windings

- SAE4:5 ventilated adaptor

- SAE4:4 ventilated adaptor

- 6.5′ or 7.5′ drive member

- Heavy-duty air cleaner

Applications

- Industrial power units in unregulated emission zones

- Small pumps and auxiliary drives for factories or remote sites

- Continuous-duty operation in ambient temperatures up to 40 °C

- Compact installations where space is constrained

- General-purpose industrial machinery with fixed or variable speed requirements

Why Choose Lister Petter TR Engines?

- Compact & Reliable: Space-saving design without compromising durability.

- Low Maintenance: 250 hour oil & filter intervals reduce downtime.

- Flexible Operation: Fixed and variable-speed options for different applications.

- Durable Cooling: Efficient crankcase air-flow and flywheel fan for temperature control.

- Field-Proven: Designed for unregulated territories with robust engineering.

Maintenance & Service Guidance

- Oil & filter change at **250 hour intervals**, depending on operating conditions.

- Check safety switches, fuel system, and cooling airflow regularly.

- Use appropriate diesel fuel and clean medium-duty air filter for maximum reliability.

- Inspect decompressor levers, flywheel cooling fan, and mechanical governor periodically.

Support & Spare Parts

- Original Lister Petter spare parts via Xanthis.gr network

- Operators’ manuals and technical documentation included

- Field service for installation, diagnostics, and maintenance

- Optional maintenance contracts for regular 250 hour intervals

Conclusion

The **Lister Petter TR Industrial Engines** are ideal for compact industrial power applications, offering **durability, easy maintenance, and flexible speed operation**. Their robust design, low maintenance intervals, and proven reliability make them perfect for industrial setups in unregulated emission zones.