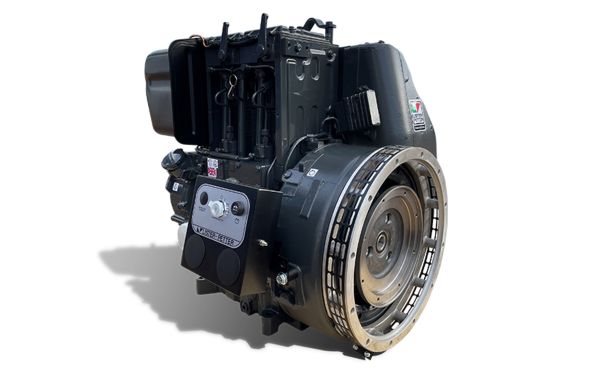

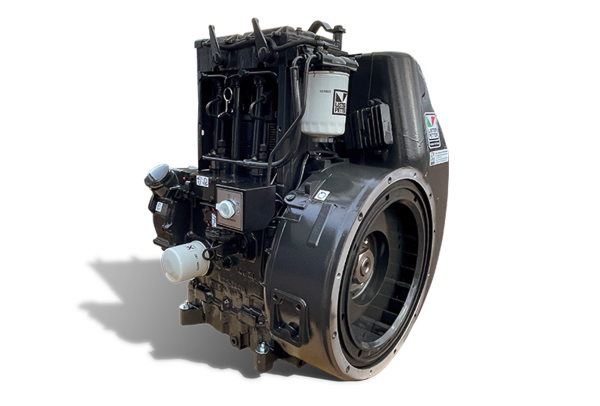

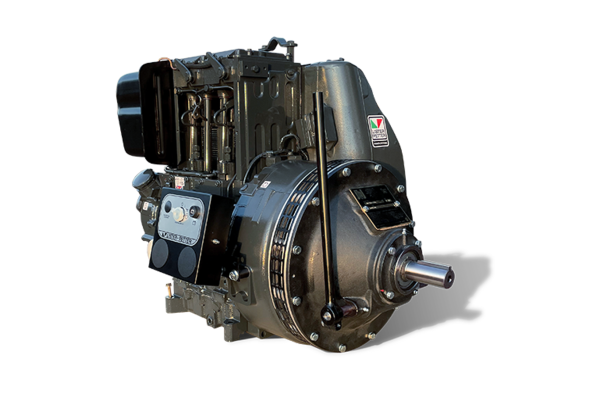

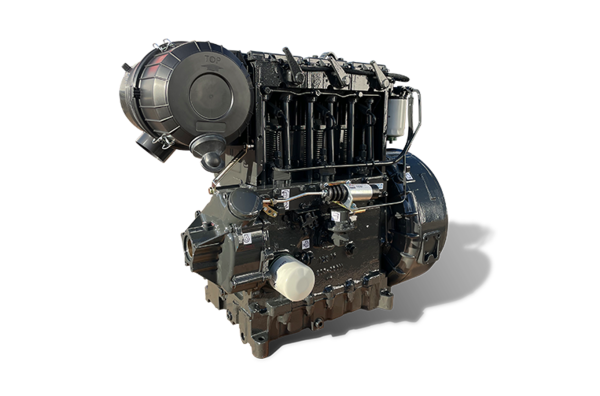

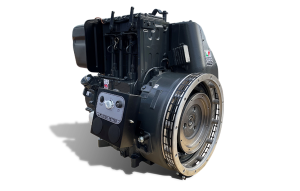

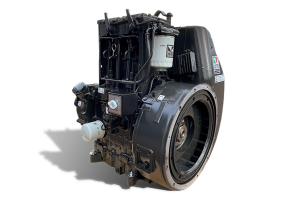

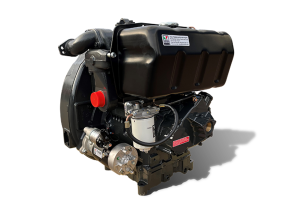

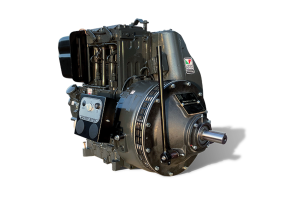

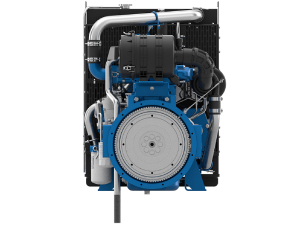

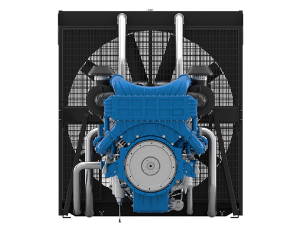

Description

TR Industrial Engines are specifically designed to be compact power unit suitable for use in unregulated emissions territories. It is durable, reliable and easy to maintain with oil and filter changes up to 250 hours, dependent on operational conditions. It is designed for operation in ambient temperatures up to 40°C (104°F).

Fixed Speeds

1500 | 1800 r/min

Variable Speeds

1500 | 2500 r/min

5.5 – 28.5 kw | 7.4 – 38.2bhp

Range

TR1 | TR2 | TR3

The TR Industrial engines come with the following items as standard:

- medium duty air cleaner *

- oil cooling by means of air flow over a deep crankcase finning

- inlet and exhaust manifolds

- fuel injection pump and self-vent fuel system

- fuel filter

- fuel lift pump *

- self-regulating plunger type lubricating oil pump

- spin-on lubricating oil filter

- decompressor levers

- flywheel with cooling fan **

- SAE flywheel housing **

- mechanical governing

- 12V starter motor *

- safety switches *

- fuel control solenoid (energised to run) *

- standard skid base packing

- 250 hour service intervals

- operators’ handbook (English) *

Optional items:

- 12V battery charge windings

- SAE4:5 ventilated adaptor

- SAE4:4 ventilated adaptor

- 6.5′ or 7.5′ drive member

- heavy duty air cleaner